Product name Brick Pavement Code 4071 Dimensions 40*40 Cm Piece per m2 6.25 Description ...

Kimya sanat technology is a good choice for investors who want to invest on small and medium scale enterprises with following remarkable advantage:

Mixer, Vibration table, Production line of artificial stone (manual and automatic), Demoulding machine, Blender, …

Training and technology transfer of artificial stone and special concrete, production line, …

production consulting, investment consulting, development consulting, marketing consulting, …

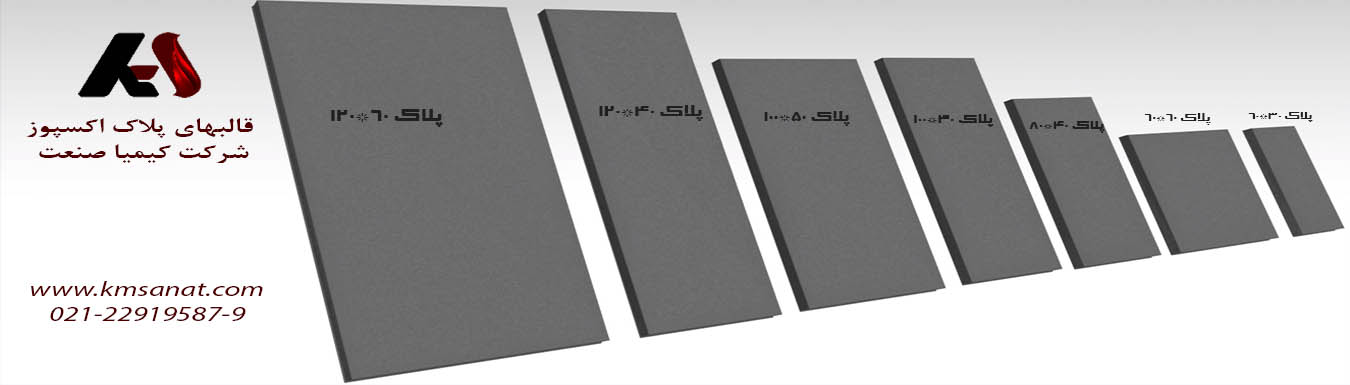

over 200 types of paving and pavement mold, facing mold, decorative mold, curb and Cornice mold

powder pigment based on iron oxide, titanium dioxide, carbon black, super plastisizer, perlite

installation of artificial stone production line, concrete equipment, blender and mixing system

over 100 types of artificial stone (pavement stone, facing stone, tiles, granite, curb and cornice and …

Kimya sanat co. has started it activities since 2006 and we are involved in designing, consulting, training and installing of factories to produce several types of artificial stones (tiles, pavement stone, facing stone, curb, cornice, …). Our artificial stone line use concrete as a raw materials and resin as a reinforcement and pigment for coloring the final product. as a new product you can see new sate of the art.

we commissioned and installed several factories in regional market and countries such as Iraq, Afghanistan, Turkmenistan, Azerbaijan and Qatar. our field of activity are design, modeling, manufacturing of several mold and chicaneries including injection molding and vacuum forming and preparation of resin and pigment.

Kimya sanat co. owns production unit with total of 3500 square meter and using 40 expert persons. we provide best quality of mold and parts of injection using best raw material of petrochemical companies.

we manufacture machinery of production line for artificial stone with automatic and manual system. our artificial stone includes more than 200 type and models and it is mixed of technique and arts.

as a matter of facts in recent years this rubbery molds for production of tiles and stones and artificial stone are common method but Kimya sanat started production of mold using composite raw materials such as ABS, PP and other polymeric alloys.

Kimya sanat co. has started it activities since 2006 and …

Building contractors, Municipality, Artificial stone manufactures, Concrete industry, Architects, …

ISO 9001, Member of A.B.C.I.C, A.I.C.S, I.M.A, I.P.M.A

Kimya sanat technology is a good choice for investors who want to invest on small and medium scale enterprises with following remarkable advantage:

variety of several products including tiles, artificial stones, most decorative parts and etc.

Flexibility of manufacturing process using Kimya sanat technology . this technology made you capable to produce as you want with variety of models and colors.

Availability of raw materials in your area.

Low investment cost for manual and automation machinery. Consequently the investment rate of retun based production capacity is below to 1 year.

Low cost of product, generally the cost of the products related to the raw materials and other overhead costs. the major consuming raw material is cement and sand and other raw materials such as pigment and resin are used in very low percent of weight.

Experienced technicians and management are the biggest capital of Kimia sanat co. Company personnel often have engineering degree with an average age of 34 years. We try to invite engineers and creative professionals to work together.

The latest blog and news about the building industry, artificial stone, concrete pieces and machines for producing concrete components are in this section. To view all news and blog, click the link “View all news and blog” at the end of this section.

Product name Brick Pavement Code 4071 Dimensions 40*40 Cm Piece per m2 6.25 Description ...

in recent ears there is several interest to use pigments. the pigments based on iron oxide(red, yellow and brown) are totally mixed...

Concrete mixing process regards to quality of mixing several items should be take consider to prepare concrete with high quality. Quality of...

Central office : no 35, Shahnazari St., Mirdamad Blv.,Tehran, IRAN

Phone : +982122919587-9

Cellphone : +989123908161

whats-app : +989100493060

Email: info@kmsanat.com

Artificial stone molds

Artificial stone production line

concrete equipment

Design and production of master molds

Training and technology transfer